High Vacuum Rebuilding and Remanufacturing

We are second-to-none in rebuilding and remanufacturing high vacuum equipment.

HOW WE DO THINGS

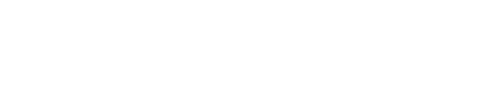

When it comes to rebuilding and remanufacturing high vacuum equipment, Metallurgical High Vacuum (MHV) is your best choice. We don’t just fix problems—we restore your equipment to its original specs and tolerances and then provide recommendations to further enhance its performance. When it comes to machining and assembly, you won’t find this level of quality, precision, and expertise anywhere else.

- Worn bearing bores are found on teardown of received equipment. We have bore gauges set to ring master gauges to determine if a bore is worn out of spec. To repair the bore, it is bored for an oversize sleeve that is shrunk in liquid nitrogen. The sleeve is then bored to the specification diameter. The problem with this operation is in locating the sleeve x and y coordinates for boring. We use proprietary fixturing that locates off the dowel pins so that the final bore is in the correct location. We do this on all pump and blower end plates received at MHV.

- Boring hinge bar bores presents similar issues. It is made more difficult since the existing worn hinge bar bore has lopsided wear. We get around this by using another proprietary fixture that locates off the dowel pin holes on the pump casting. Now the final overbore is located at the original x and y location.

- In the case of blowers, MHV locates the bore properly in order to hold impeller centerlines ensuring proper gear backlash.

Metallurgical High Vacuum is the leader in Stokes microvac rotary piston pump remanufacture. We manufacture and machine most components ourselves, and because of this have developed improvements to the original Stokes design, saving you money, and negating costly downtime.

These optimizations include:

- Full Pressure Lubrication/Failsafe Lubrication: We are the only high vacuum equipment service provider in the nation offering this optimization for Stokes 412H11 and 412J14 pump models.

- Long Key Mainshafts – Permits the reuse of eccentrics with worn keyseats, an improvement for Stokes 412H10 over OEM Woodruff keys.

- Interference Fit Repair Sleeves – Maintains durability and longevity of eccentrics and piston slides, MHV never uses set screws or anaerobic adhesive in these applications.

- Submerged Arc Shaft Welding – This process is fast and allows build up of worn shafts on blowers and pumps. After welding, the shaft is lathe turned and then ground to size. This process eliminates “spray metalizing” (a common practice for other remanufacturers) and produces a metallurgically sound solution to shaft rework. It can be applied to carbon and low alloy steels along with ductile iron material.

- Single Plane Dynamic Balancing – Reduced vibration for quieter operation and increased operational life (offered for Stokes 412, MHV HS430).

- TEFC Motor with VFD – motor replacement on Stokes 412 rotary piston pumps offer substantial energy efficiency improvement, and offer our clients considerable cost savings.

Metallurgical High Vacuum’s options for optimizations extend beyond vacuum pumps. Thanks to our in house submerged arc welding capability we save our clients money on oem shaft replacements by extending the life of the existing shaft. Our manufactured mechanical seal conversions and sourced low helix gear sets also dramatically increase blower/vacuum booster longevity.

- Mechanical Seal Conversions – Improved product design (offered for Stokes – 306, 310 blowers, Roots – 607, 615 blowers)

- 20o Low Helix Gear Sets – Reduced axial bearing loads caused by the 45o helix on OEM gear sets (offered for Stokes 607, 615, 622 blowers)

- Submerged Arc Shaft Welding – This process is fast and allows build up of worn shafts on blowers and pumps. After welding, the shaft is lathe turned and then ground to size. This process eliminates “spray metalizing” (a common practice for other remanufacturers) and produces a metallurgically sound solution to shaft rework. It can be applied to carbon and low alloy steels along with ductile iron material.

Corrosion Resistant Alloy Overlays – Increased operational life for liquid ring pumps used in aluminum chloride applications.

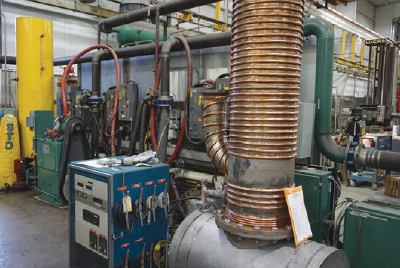

Unmatched Vacuum Pump Testing

We start by conducting a thorough analysis of your pumping equipment and put each piece through rigorous testing to ensure it will perform as expected in your system. Our commitment to you and your equipment is why vacuum process manufacturers across North America seek us out for our expertise.

Vacuum Pump Tests

Our unique testing approach sets us apart from the competition. For vacuum pumps, we conduct:

Hot/Run Test & 24 Hour Run

Ensures the pump operates smoothly.

Dynamic Balancing

Reduces vibration, extending pump life.

Drawdown

Validates pump performance against OEM specifications.

Diffusion Pump Tests

For diffusion pumps, our tests include:

Blank-Off

Demonstrates the ultimate lowest vacuum pressure under standard HOT running conditions.

Throughput

Shows how the pump will perform under load, guaranteeing long-lasting performance. Typically used to test oil boosters.

On-Site Services

Need assistance at your location? We’re ready to come to you. Our on-site services are designed to provide immediate, efficient solutions right at your doorstep.

Vacuum System Troubleshooting

Not sure what’s wrong? No problem. Our team is ready for any challenge and thrives on learning the idiosyncrasies of your systems, applying our expansive knowledge of industry processes, and identifying issues to improve efficiency. Trust MHV to keep your vacuum systems running at their best