How to Lower Lifetime Pump Cost with Smart Maintenance

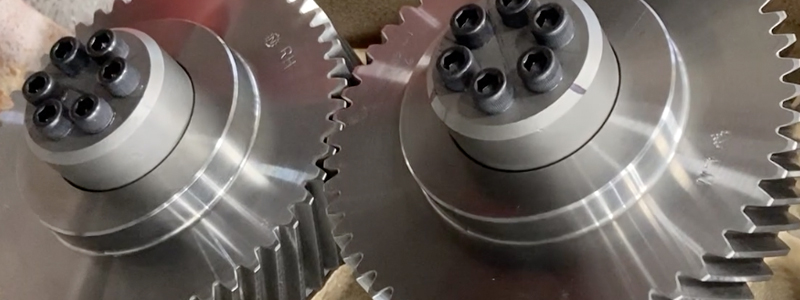

Industrial furnaces are costly and valuable assets. They need periodic maintenance to keep them running. This maintenance includes rebuilding or replacing components, controllers and even vacuum pumps.

Here’s where it can get complicated, because furnaces can have a decades-long life when maintained properly. Shut downs (especially unplanned ones), however, cost production time and repairs that get expensive. Experienced users look beyond low initial costs to determine the cost of ownership over the long run.

So, what can a smart technical support department do about it? They can keep good system performance records like pump-down and processing times, ultimate pressure, cycle times, etc. These can help to understand what is happening with a system over time. Look for things like changes in parts, materials, preparation or maintenance. When vacuum furnace cycles run long or the ultimate pressure can’t be attained, it can be caused by vacuum leaks, contamination or malfunctioning pumps.

If you have spares on hand, you can swap out the malfunctioning pump or blower with minimum downtime and get started on repairs or rebuilding.

Pump Rebuilding

Do you fix them in-house or send them out? This depends on many issues, but it boils down quickly to time and money. Economics may dictate that rebuilding your Stokes, Kinney, Leybold or other brand pump makes the most sense. Purchasing decisions can look like just a matter of price. In real life, though, it gets more complicated. Proper analysis of your total cost is needed to evaluate the differences in rebuilds from different vendors, and it can show you how to get $60,450 more in profits.

Tables 1 & 2 show the true value of a Stokes 412 pump rebuild over a five-year period. This information was provided by a client.

Cost of ownership becomes clearer as you look at annual costs. These figures are for illustration only, as the labor rates and hourly costs vary, but you can see how an estimate can help solve the problem if you look beyond the initial cost. The difference in initial costs ($9,300 vs. $22,325) is reflected in the monthly cost differences ($1,380/month vs. $372/month) once you look at the long-term results. The total life cost ($82,775 versus $22,325) becomes $60,450 saved over the five-year life of the pump. So, from 17 months on the savings are pure profits to the company.

There are a lot of detailed reasons why a better-remanufactured pump will last longer, and Metallurgical High Vacuum would be happy to provide you with those details. All you have to do is contact us.

| Item | Vendor X | Cost for 5 years of service | Notes |

|---|---|---|---|

| Initial rebuild cost for 9 months of service | $7,500 | $52,500 | Process contaminants wear pump quickly |

| Maintenance cost to swap pump | $500 | $3,500 | Labor – in-house time (7X) |

| Shipping expense | $325-up | $2,275-up | Freight (7X) |

| Furnace downtime (1 day per rebuild) | $2,500 | $17,500 | Production lost – # of days @ $105/hour |

| Rejected parts –depends on items/load | $1000-up | $7000-up | Customer relations damaged |

| Total | $9,300 | $82,775 | |

| $1,380/month |

| Item | Vendor M | Cost for 5 years of service | Notes |

|---|---|---|---|

| Initial rebuild cost for 60 months of service | $18,000 | $18,000 | On-board filters remove contaminants |

| Maintenance cost to swap pump | $500 | $500 | Labor – in-house/time |

| Shipping expense | $325-up | $325-up | Freight |

| Furnace downtime | $2,500 | $2,500 | Production lost – 1 day @ $105/hour |

| Rejected parts –depends on items/load | $1,000-up | $1,000-up | Customer relations damaged |

| Total | $22,325 | $22,325 | |

| $372/month |